Dental Cleaner DTC Economy

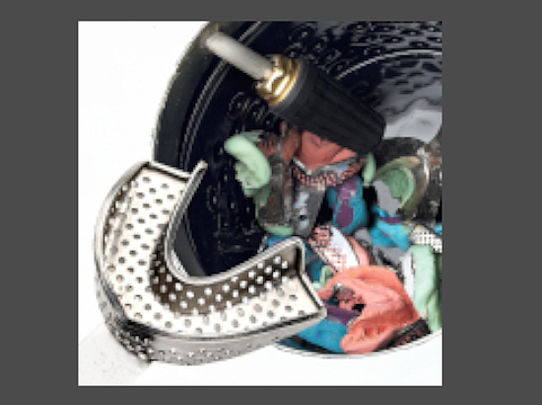

The conventional manual cleaning of dental trays and retention plates is extremely labour intensive. Wassermann’s full automatic DTC Economy does the same job in a few moments.

Range of application:

The cleaner is able to clean 25 dental trays in 2 minutes and 50 retention plates within 1 minute, without preparation, just using tap water. The dental trays including imprint of alginate or silicon’s as well as the retention plates with gypsum can be placed into the drum. No need to worry about a thing, you can focus on your core activities.

Major features at a glance:

- Pressure cleaning unit for perfectly cleaned metal or plastic dental trays and retention plates made of plastic

- Time saving: Completely automated cleaning without prepping

- Complete removal of residues like alginate, silicone or similar material from impression trays and plaster debris from counter plates

- User-friendly operation

- Optimal results with just a push of a button

- Permanent water supply - simply connect a water line

- Quick and easy installation

- Sustainable & economical: The system uses only cold water for cleaning without further chemical additives

- Cuts the costs for expensive chemicals

- Clean wastewater thanks to high quality filtration: Alginate, silicone and plaster debris all collects in a catch tray and does not enter the sewage system

Included in delivery:

- Supply line

- Supply hose

- Discharge hose

| Technical Specifications: | |

|---|---|

|

Voltage |

220–240 V / 50/60 Hz |

|

Power consumption |

12 A |

|

Output |

2700 W |

|

W x H x D |

490 x 575 x 510 mm |

|

Weight |

79 kg |

|

Sound level |

≤ 70 dB (A) |

|

Water supply |

3/4“ at the tap, min. Ø 15 mm, |

|

Water Consumption |

7-8 l/min |

|

Capacity |

25 dental trays or 50 retention plates |

For spare parts / accessories store:

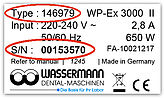

Example of an identification plate at your device

Type = item number

S/N = serial number

The serial number allows us to find quickly without any doubt the correct answers for the needs of your machine. The identification plate is located on the back or right side of your unit.